THIXOMOLDING

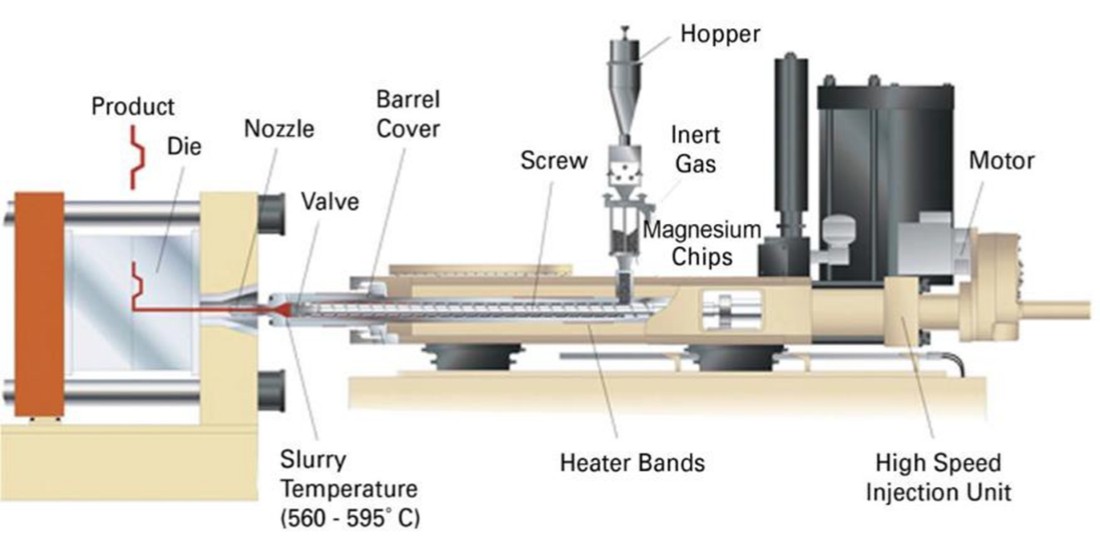

Thixomolding® is a casting method where magnesium is simultaneously sheared and heated until it becomes dough-like in consistency, and then injected into a mold, creating a laminar flow front similar to that of plastic injection molding. The doughy consistency is created in a magnesium injection molding machine under a protective gas. The magnesium is heated to 560° to 600° C via a feed screw and external heating, and then pressed into the die. The duration of the injection process including dwell-pressure is about 0.03 seconds; the cycle time, depending on component size, is about 20 to 45 seconds. The laminar flow front created during the Thixomolding® process ensures the production of components with more uniform material structure and lower porosity and/or cavity-free compared to die casting.

Or, more simply

Injection Molded Magnesium

THIXOMOLDING PROCESS

THIXOMOLDING BENEFITS

- Light weight

- Thin walls: .020” minimum (.5 mm)

- Castability and stiffness

- EMI-RFI shielding

- High strength to weight ratio

- High dimensional stability and tight tolerances

- Linear tolerances: ±.001 in. (0.003 cm) for each inch of dimension

- High quality surface finish

- Low porosity: 50% lower than die cast

- Dent resistance and good machinability

- Sound and vibration dampening

- Heat transfer capability

- No surface sinks at wall junctions

- Low draft: 0 draft possible, .5 to 2 degree is typical

- Recyclability and low warpage

- Environmentally friendly process

- Insert molding possible

MATERIAL PROPERTIES

| Alloy | Elongation % | Modulus (Gpa) | Yield (Mpa) | Tensile (Mpa) | Specific Gravity |

| AM60B - Die Cast | 6 | 45 | 130 | 220 | 1.70 |

| AM60B - Thixo | 14.8 | 45 | 145 | 280 | 1.70 |

Die Cast Properties provided by Meridian

Thixo Properties are average of 8 samples: Elements Lab 6/5/2015